The perfect laser solution for a better surface finish of the weld is called Mega 6.0

Professional welding laser to perform micro-welds, an evolution of the Mega SILVER, inherits all the best features of this family, such as the large welding chamber and the double cooling system.

What distinguishes it most are the new upgrades developed internally by Elettrolaser which guarantee greater energy efficiency and better quality of the laser shot. The new shell design, in resistant and eco-friendly material, was introduced to respect the new principles of environmental protection.

Equipped with SMOOTH SPOT technology, it allows easier distribution of the filler material and a better surface finish of the weld. Developed mainly for those who weld silver and / or highly reflective materials, and for intensive productions, which aim to digitize their business. The Mega 6.0 can also be equipped with the 3D VISION system for a stereoscopic view of the welding area.

NO MORE PROBLEMS

FOR SILVER AND

REFLECTIVE MATERIALS

It facilitates the silver welding thanks to the innovative cavity and its special resonator.

Improved surface finishing of the welds and better distribution of the filler material.

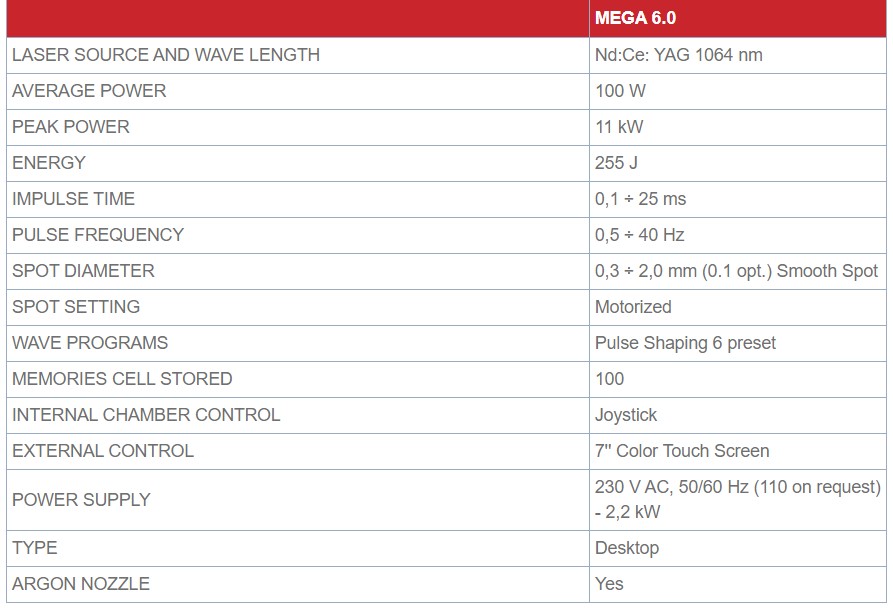

Main features

- Big laser road

- Smooth and filled spot

- Integrated camera

- 7” color touch screen display

- Demonstration videos uploaded

- Stereomicroscope 10x by Leica

- Double powerful integrated cooling system

- Powerful lamp

- High energy real available along the process

- Ethernal port RJ 45 included

Applications

- Welding precious metals like platinum, titanium, gold, silver, palladium

- Repair of antique jewelry

- Repair of settings without removing the stones

- Tennis bracelet claps repair

- Repair of watches, eyewear (nose pad, pad arm, hinges, frames, etc.) and other minutia

- Welding of elements using filler material without the need of additional cleaning

- Repair of casting defects such as porosity or cracks

- Welding and repair of bridges, implants, prosthesis, dental appliances and much more

- Mold and die reparation

- Dental applications (repair of dental bridges, caps, plants, orthodontic dental braces, chromium-cobalt and titanium casting porosity)

- Welding of objects, usually inaccessible with welding flame or arc