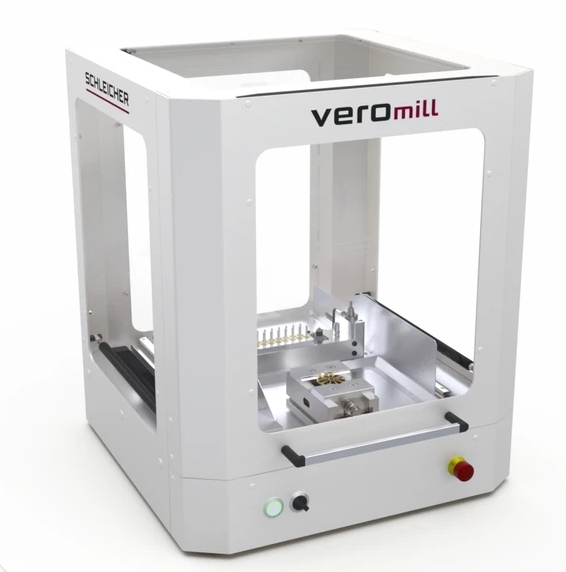

Veromill

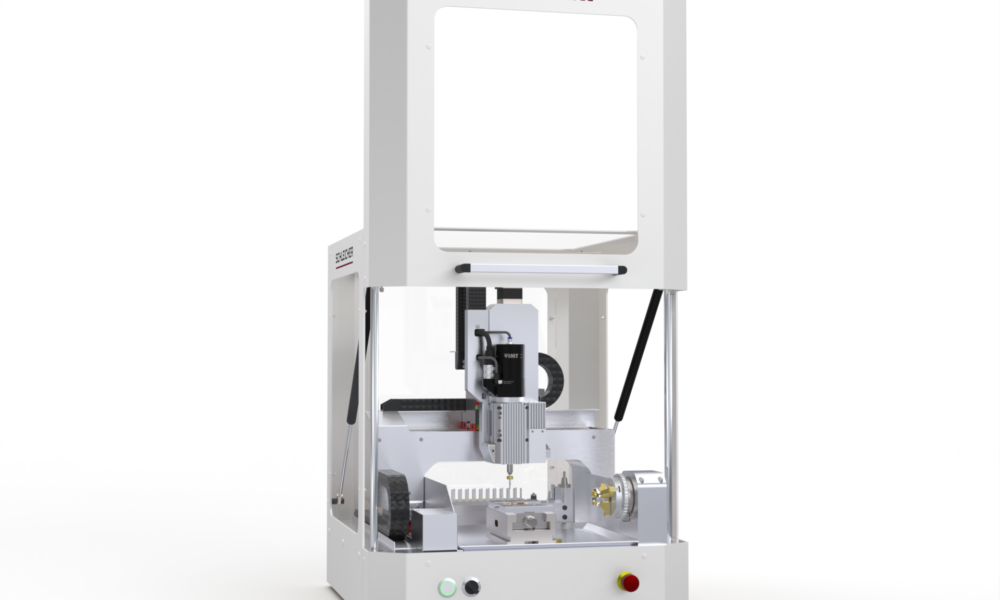

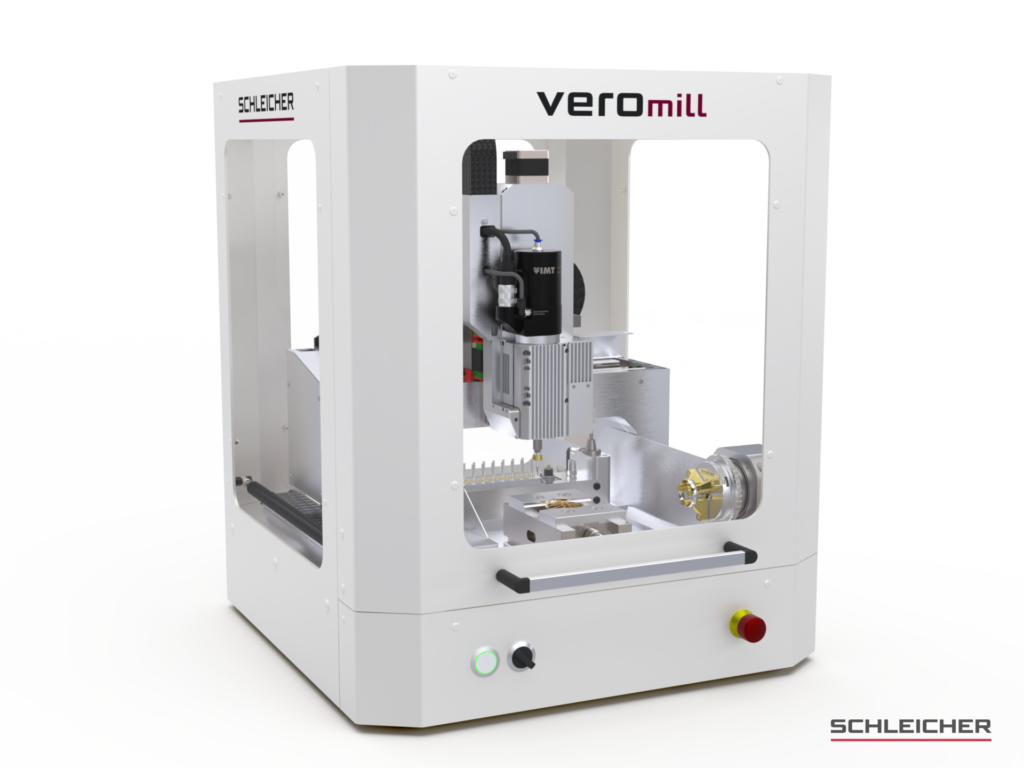

Discover the Veromill™—a precise and compact milling center designed for micromachining and micromilling. With its innovative design, the Veromill™ offers exceptional stability and precision, all within a small footprint.

Applications and industries include:

- Jewelry manufacturing

- Watchmaking

- Engraving

- Rapid prototyping

- Micromilling

- Stamp and tool manufacturing

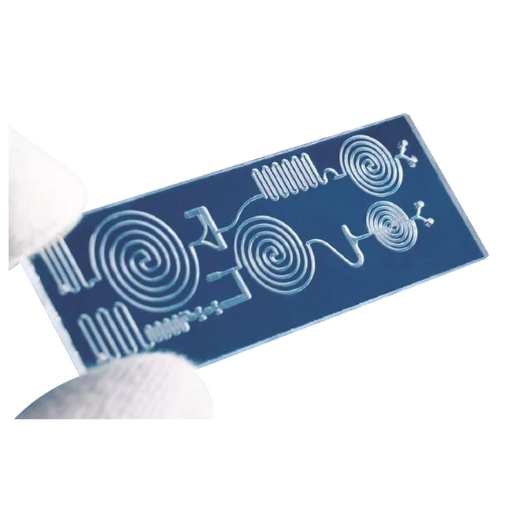

- Microfluidics

Made in Germany

Veromill™ Milling Machine Features

High Precision

- Innovative design, high-quality components, and precise assembly ensure top precision for jewelry milling.

High Structural Stability and Stiffness

- Compact yet stable, guaranteeing superior surface quality in all machining tasks.

Automatic Tool Change

- Integrated tool changing system with 23 tool stations for automatic, complex applications.

Tool Cooling and Lubrication (MQL)

- Standard integrated cooling and lubrication extend tool life and improve surface quality.

High-Speed Milling Spindle

- Achieves speeds up to 60,000 rpm for increased cutting speeds and feed rates.

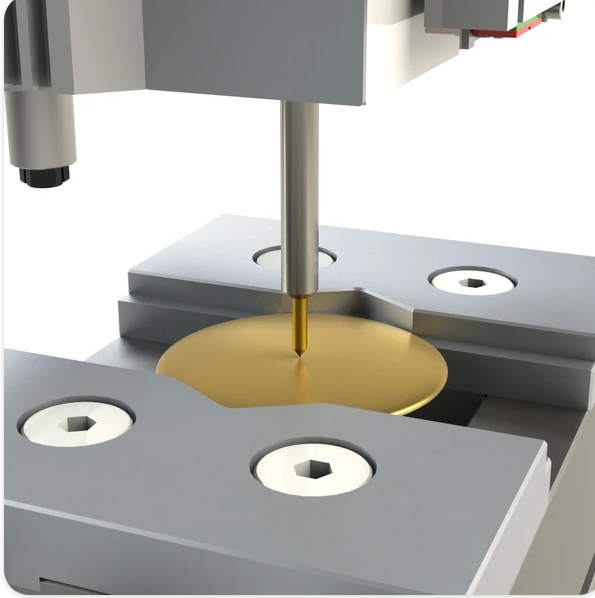

Touch Probe for Curved Surfaces

- Built-in measuring system for easy engraving on curved or uneven surfaces.

Product features of the CNC milling machine

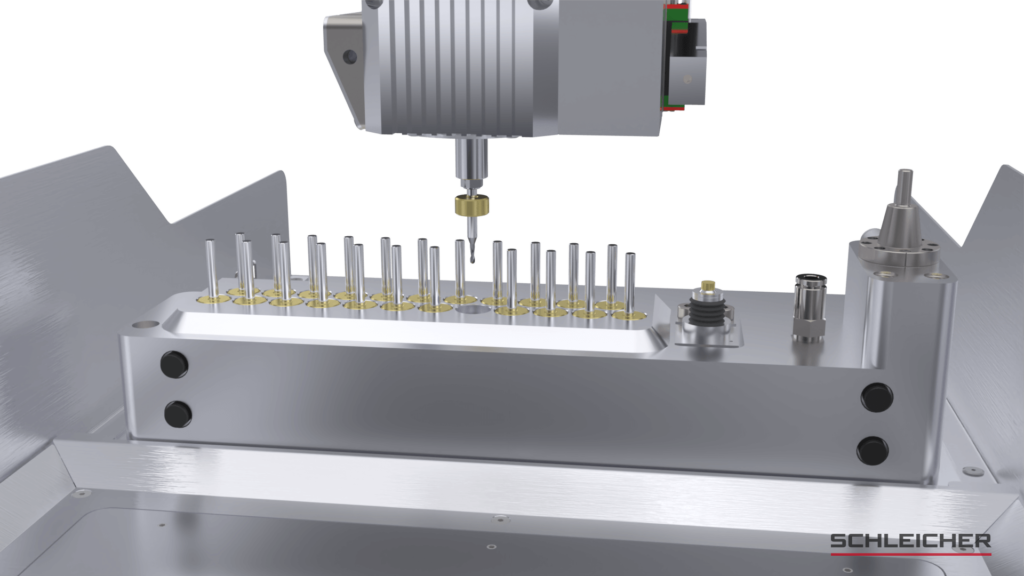

Automatic tool change with the milling machine

The Veromill™ machining center has an automatic tool change system, enabling seamless, automated tool insertion and exchange. It features 23 slots and a measuring tip holder, with a tool length sensor for accurate adjustments. Tools are pneumatically clamped using a collet chuck. The tool magazine is located at the back of the machine, safely separated by a transparent panel.

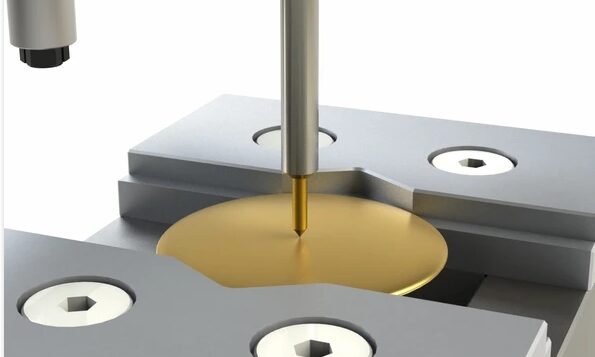

Minimum quantity lubrication for cooling and lubrication of the tools

The CNC milling machine features automatic tool change as standard. It includes fully integrated tool cooling and lubrication using minimum quantity lubrication (MQL), which cools and lubricates milling tools with air and spray mist during machining. This significantly extends tool life and enhances surface quality, especially for jewelry. The lubrication system’s spray head is seamlessly integrated into the spindle block of the CNC machine, eliminating the need for manual adjustments.

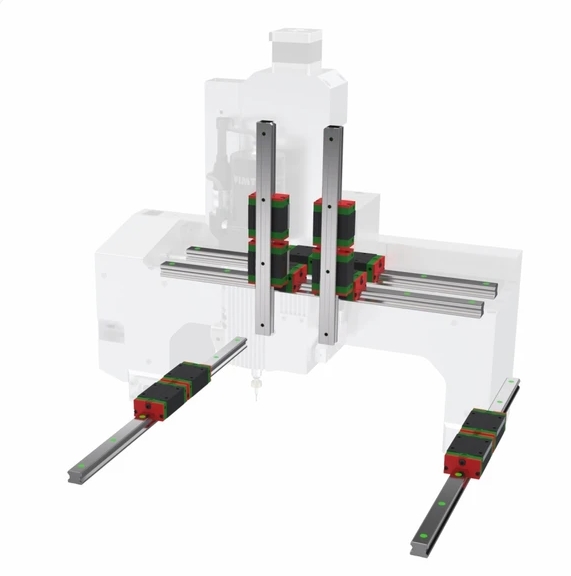

High structural stability

The compact milling center features backlash-free and stable guides, which are directly mounted onto the machine’s solid base supports. This setup ensures maximum rigidity and precision, directly impacting the quality of your products. The axis drives of the Veromill™ utilize preloaded recirculating ball screws, providing absolute freedom from backlash, longer tool life, and more precise milling.

High-precision milling spindle with automatic tool change

The integrated high-performance milling spindle ensures higher cutting speeds and feed rates. This allows for speeds of up to 60,000 rpm. As a result, engraving and milling times are significantly reduced. The optimal speed can be variably set depending on the material or tool. The tools are always clamped at the center of the milling spindle using a collet chuck, ensuring a long tool life due to optimal concentricity. Tools are clamped via pneumatically actuated direct shaft clamping, which enables automatic tool changes.

Measuring system for curved surfaces

The CNC milling machine’s fully integrated measuring system is unique. This allows curved surfaces to be milled or engraved quickly and easily. Drawings and designs can be simply created in 2D, while the Veromill™ machines the curved surfaces in 3D after automatic measurement. This is an advantage over conventional engraving depth controllers, where the engraving depth has to be set manually. In addition, the electronic height compensation increases tool life, as the optimum cutting depth for the tool is used.

Innovative machine housing

The safety concept of the jewelry milling machine features a robust cube-shaped sheet metal housing. Transparent glass panels provide an optimal view of all machine components. The CNC milling center is equipped with a front lifting door, making it easy to open and load jewelry and workpieces from the front. High-performance LED strips are installed in the upper part of the housing, ensuring optimal illumination of the machine interior at all times. Impress your customers with the innovative housing design of the Veromill™.

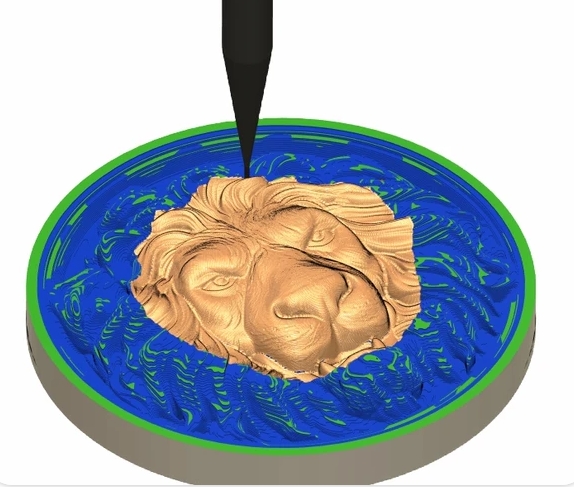

Complex milling or 3D engraving

Whether you’re producing simple engravings, complex milling, or 3D engravings, the Veromill™ provides ample flexibility, stability, and potential for a variety of machining operations. All axes of the CNC milling machine are precisely and simultaneously controlled. Depending on the machine variant, it supports either 3- or 4-axis simultaneous milling.

Application Examples of the Engraving Machine

Technical Data of the CNC Engraving Machine

Technical data of the compact machining center

| Machine model | Veromill™ |

| Technology | CNC engraving / CNC milling / CNC diamond engraving |

| Dimensions | 490 mm x 540 mm x 570 mm 19.29 in x 21.25 in x 22.44 in |

| Weight | 65 kg |

| Machine Types | 3-axis simultaneous / 4-axis simultaneous |

| Machine guides | Backlash-free precision linear guideways |

| Max. Object size flat machining (W x D x H) | 202 x 205 x 98 mm |

| Drive elements | Backlash-free preloaded recirculating ball screw drives |

| XYZ axis travel | 220 mm (X) x 260 mm (Y) x 114 mm (Z) 8.66 in (X) x 10.23 in (Y) x 4.48 in (Z) |

| Multi-purpose machining area | 180 mm (X) x 142 mm (Y) x 80 mm (Z) 7.08 in (X) x 5.59 in (Y) x 3.15 in (Z) |

| Max. Material height | 111 mm (4.37 in) |

| Outer cylinder diameter (rotation) | Max. ⌀ 116 mm (⌀ 4.56 in) |

| Engraving and milling spindle | Precision high-frequency spindle Automatic tool changer, pneumatic Speed: max. 60,000 rpm Power: 300 watts Concentricity (clamping taper): <0.001 mm (<0.000039 in) Tool shank: max. ⌀ 4 mm (⌀ 0.157 in) |

| Tool magazine | 23 tool positions + probe tip holder incl. tool length sensor |

| Tool cooling and lubrication | Integrated, liquid and air cooling (MQL) |

| Rotation axis | Precision rotary axis, harmonic drive gearbox, backlash-free |

| Applications | Jewelry manufacturing, watchmaking, engraving, prototyping (rapid prototyping), stamp and tool manufacturing, micromilling and micromachining, microfluidics, science and education, milling jewelry, engraving jewelry and rings |

Picture of milling machine for jewelry