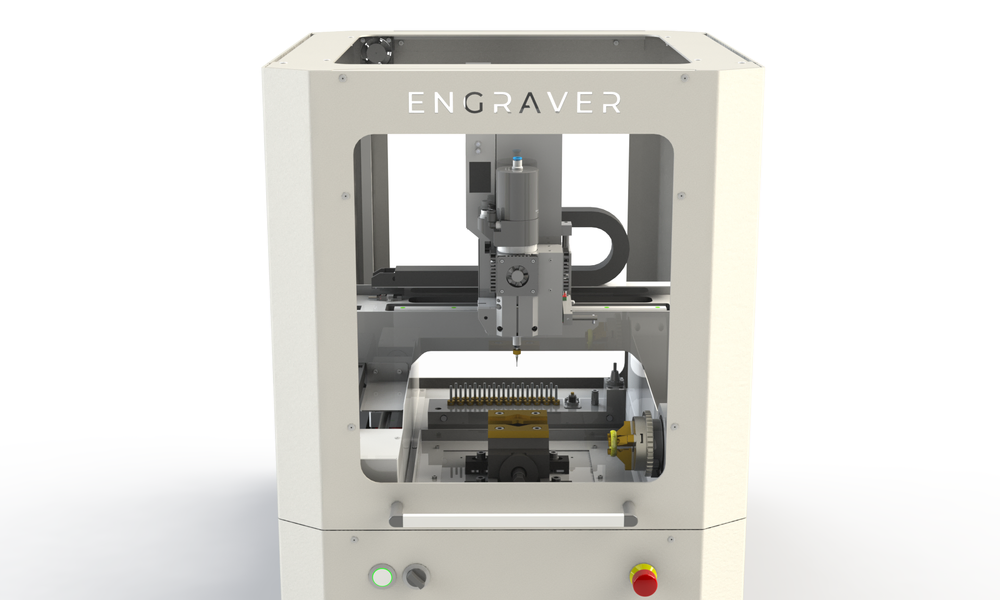

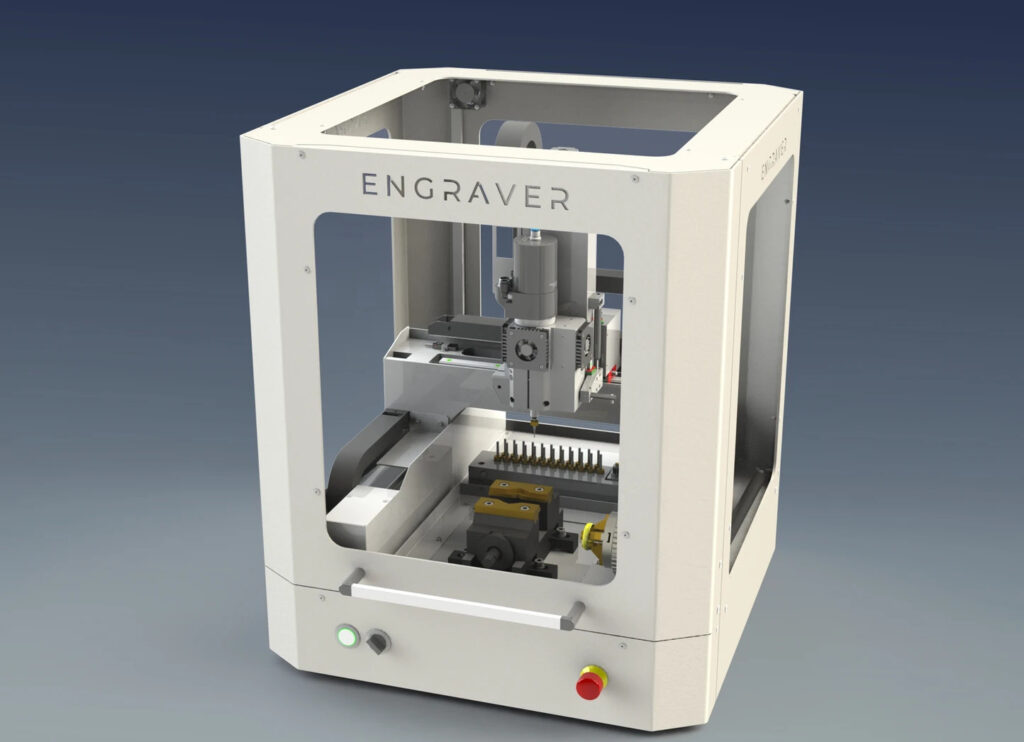

Engraving Machine

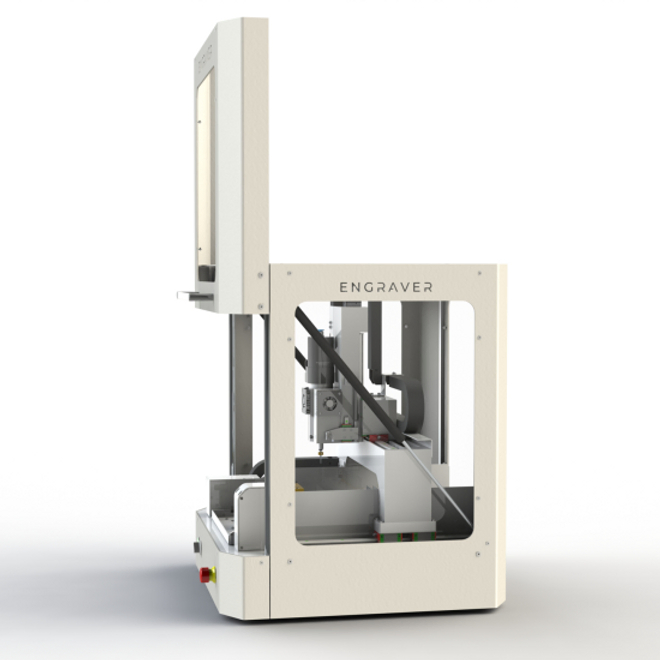

Milling and Engraving Machine : Discover the ENGRAVER, the innovation for milling and engraving jewelry or workpieces. Precise and flexible, the engraving machine adapts perfectly to your applications, products and jewelry. An asset for every workshop and every store.

Made in Germany

Visit Manufacturer link

Precise engraving machine.

The rock-solid engraving machine design guarantees highest precision during engraving or milling of your jewelry. Basic components accurate to the millimeter, the use of high-quality machine components and exact assembly result in a precision that leaves nothing to be desired. Precision made in Germany.

Powerful jewelry engraving machine.

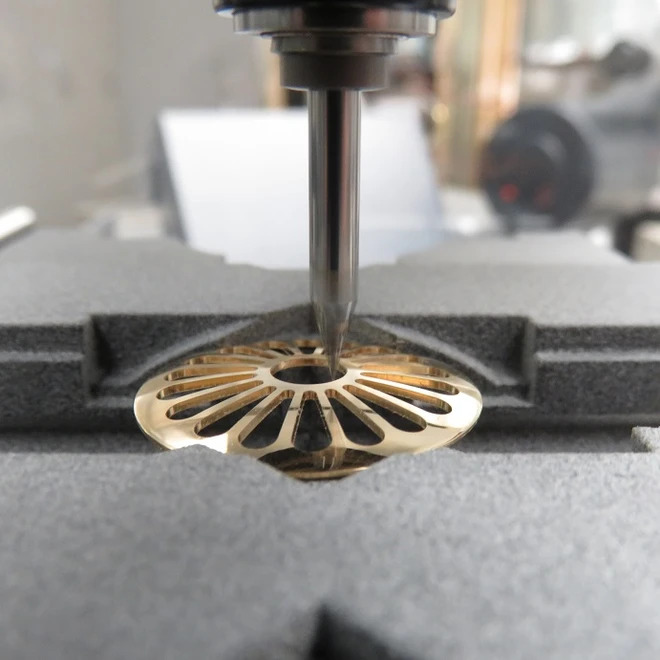

Due to the innovative machine concept, our jewelry engraving machine achieves the highest stability and rigidity. Reduce your tool wear and get machining surfaces of the highest quality. Highly polished machining surfaces are achieved when engraving with the CNC milling machine, giving your jewelry and workpieces an incomparable value.

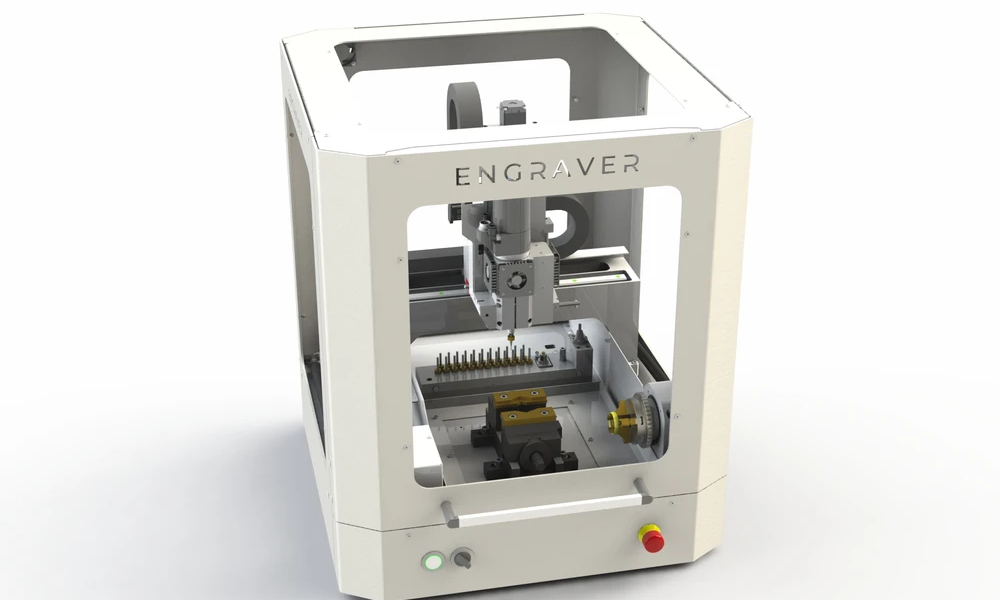

Unique milling machine.

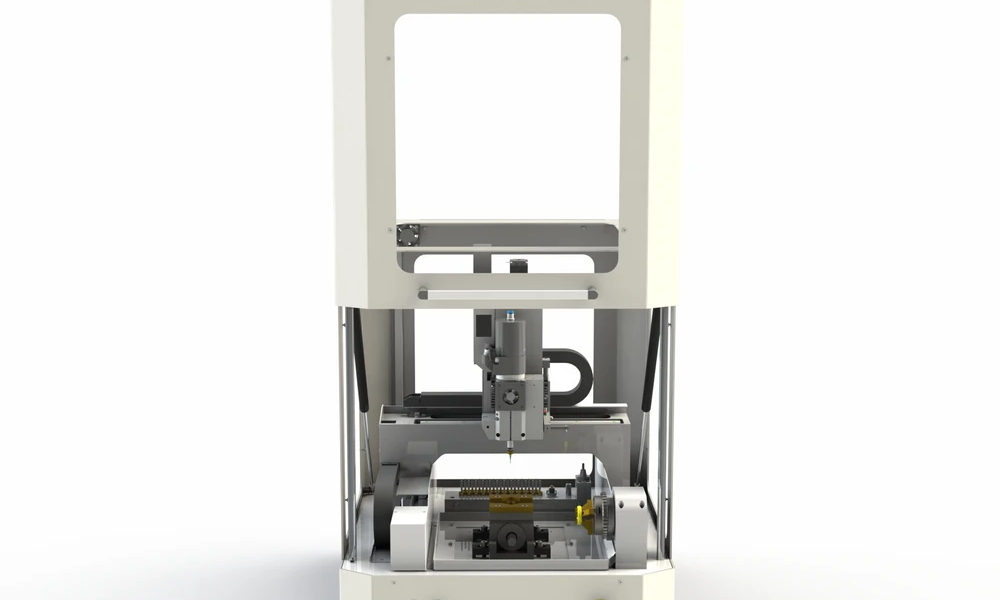

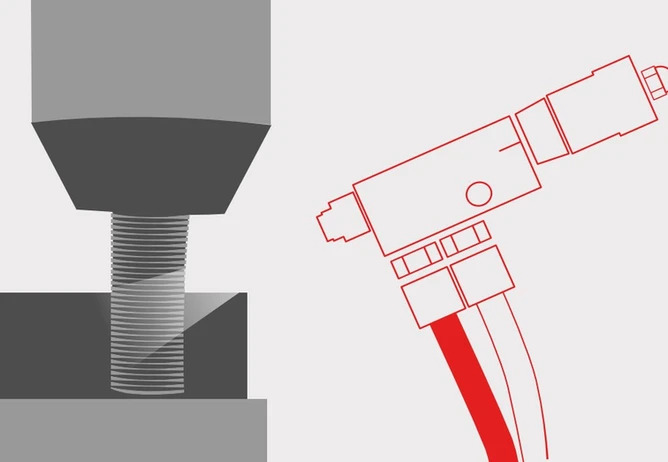

The patented measuring system integrated into the engraving machine enables you to precisely measure your workpiece surfaces. The measurement data thus obtained is used to compensate for curved or uneven workpiece surfaces. This allows you to machine curved and three-dimensional jewelry surfaces despite simple 2D drawings. This novel machining process is a technical revolution for which we have obtained a patent. In addition, electronic compensation reduces tool wear and manual adjustment of engraving depths is a thing of the past.

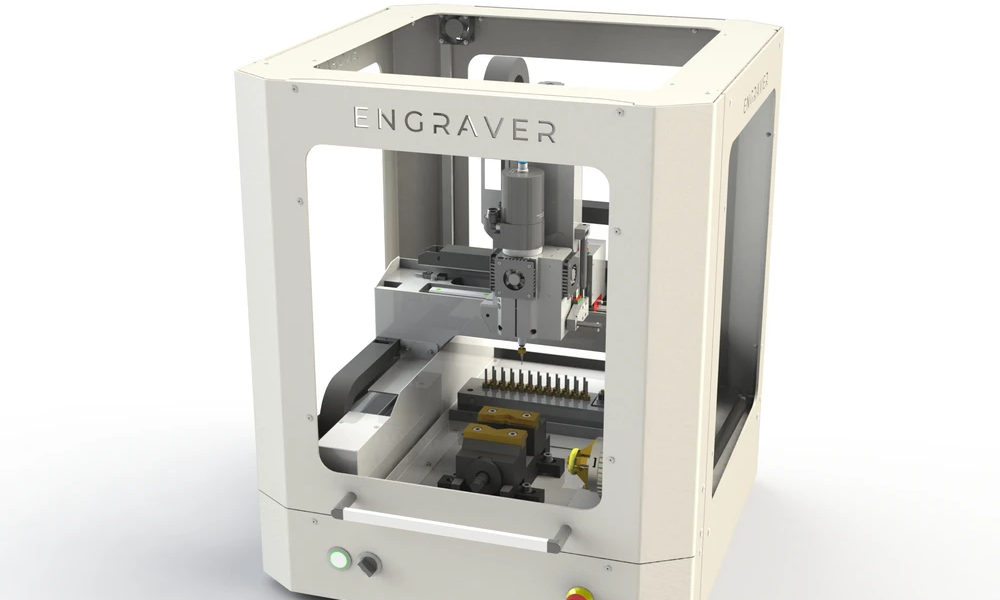

Automated CNC engraving machine.

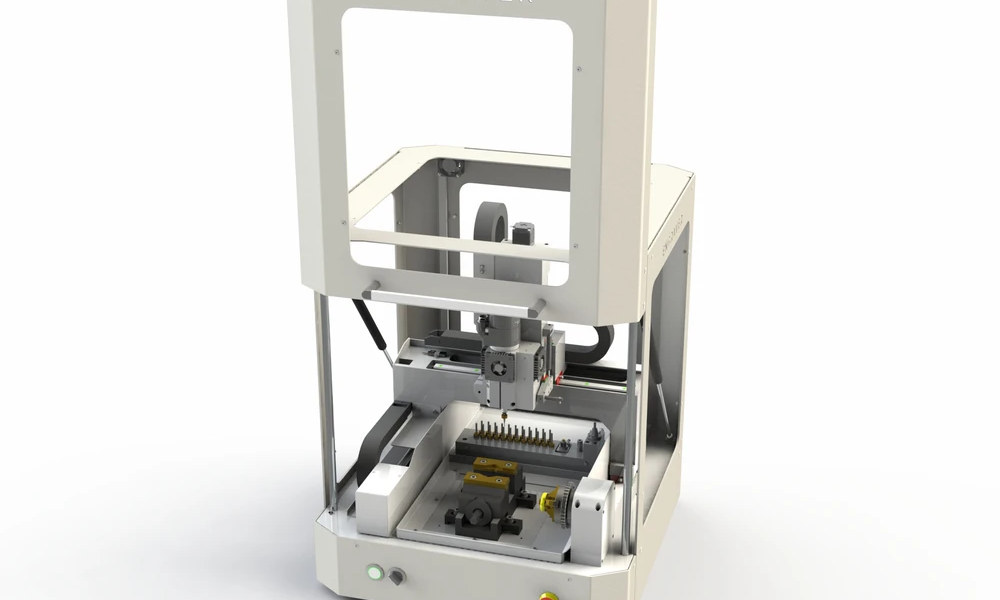

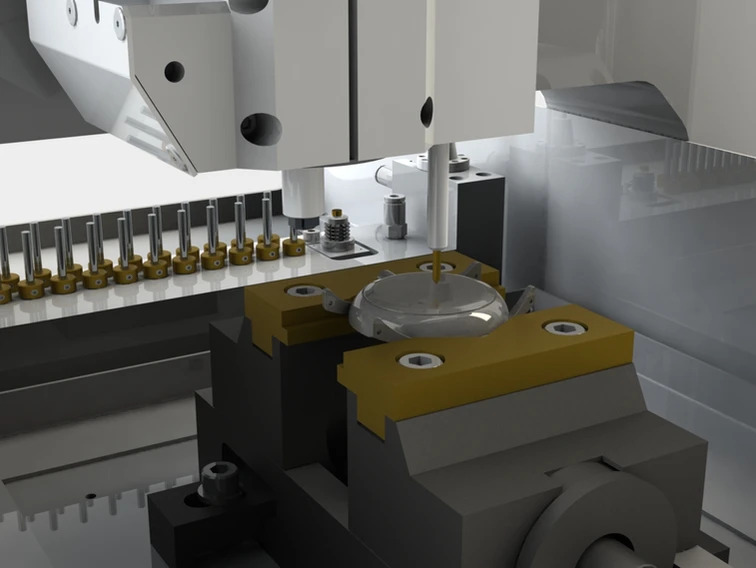

Thanks to the integrated tool changing system with a capacity of 23 tool stations, you can also process more complex applications automatically. Various machine cycles automatically set up the CNC engraving machine for your workpiece.

Machining Types of the Engraving Machine

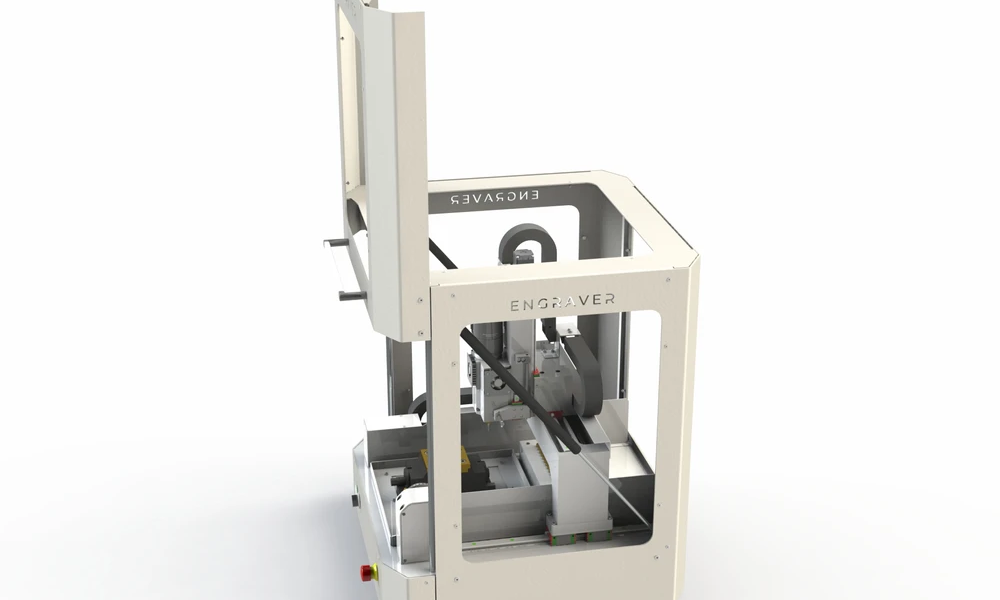

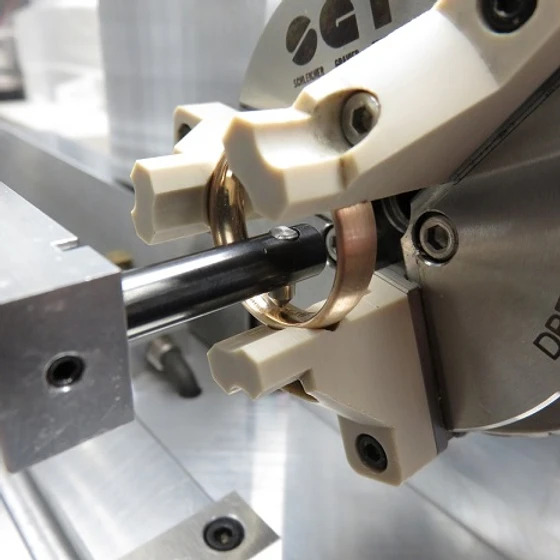

Round inside machining with the engraving machine for jewelry

Refine your jewelry or workpieces with high-quality deep engravings that are second to none. No matter if ring or bracelet. With the engraving unit of the CNC milling machine, you can process any piece of jewelry from the inside. The rotary axis of the engraving machine clamps and rotates the workpiece around its own axis. Specially designed interchangeable clamping jaws clamp your workpieces stably and with repeatable accuracy. The spring force of the scribe engraving unit can be precisely adjusted to the material to be engraved.

Round outside machining with the CNC engraving machine

Outside engraving of round jewelry takes place with the milling spindle. Mill and engrave all imaginable patterns and fonts into the workpiece surfaces.you are welcome to ask us for clamping solutions specially adapted to your needs.

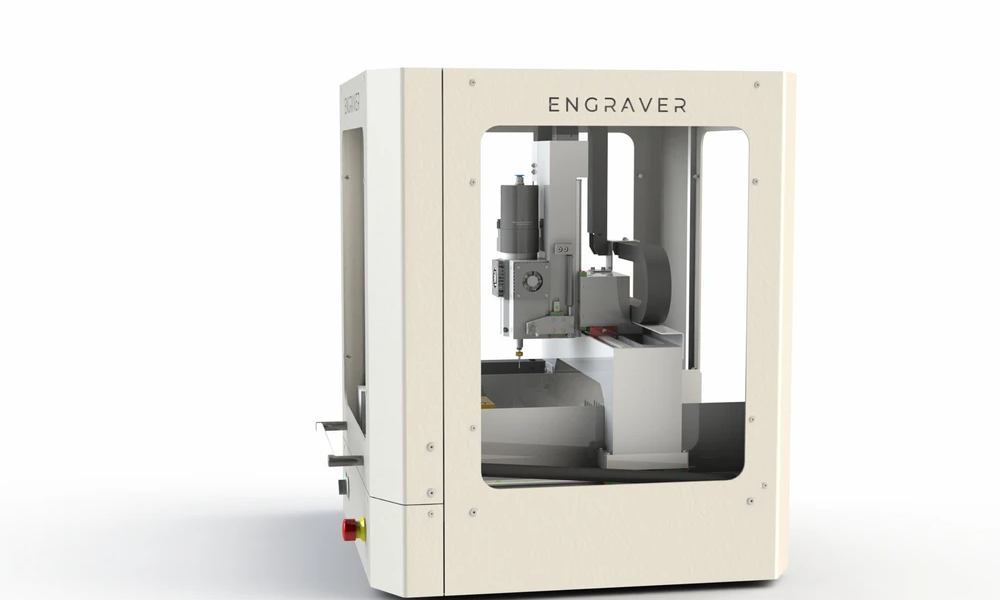

360 Degree View of the CNC Milling Machine

Main Features of the CNC Engraving Machine

Automatic tool change with the milling machine

The ENGRAVER has an automatic tool change. With this, you can automatically insert and exchange your tools. Engrave or mill your jewelry with different tools without interruptions and fully automated. The tools are clamped pneumatically by means of a collet chuck. The tool magazine of the engraving machine includes 23 places and a receptacle for the measuring tip. The magazine includes a tool length sensor to correct the different tool lengths. The tool magazine is located safely and separately in the rear interior of the milling machine.

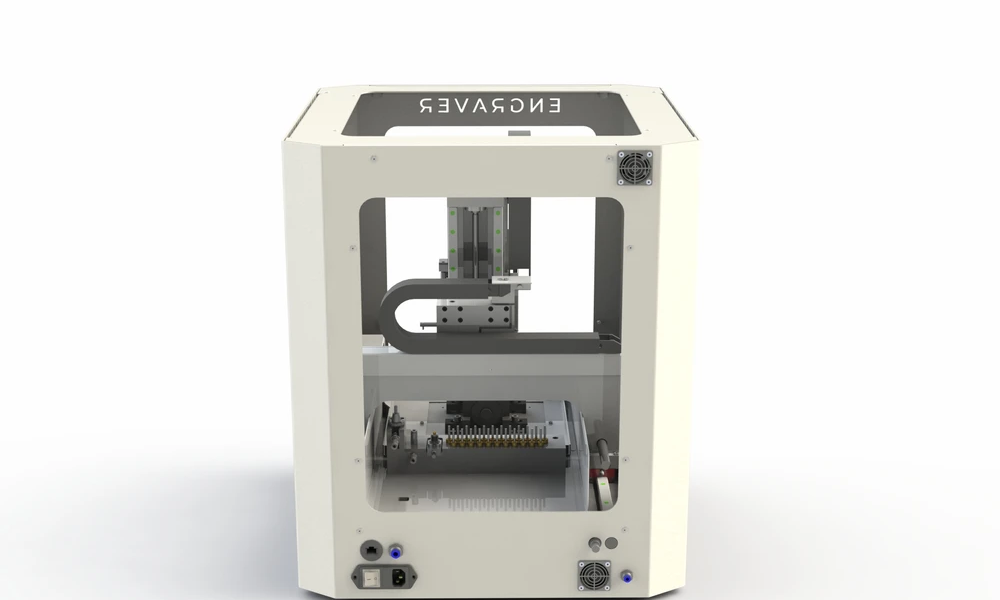

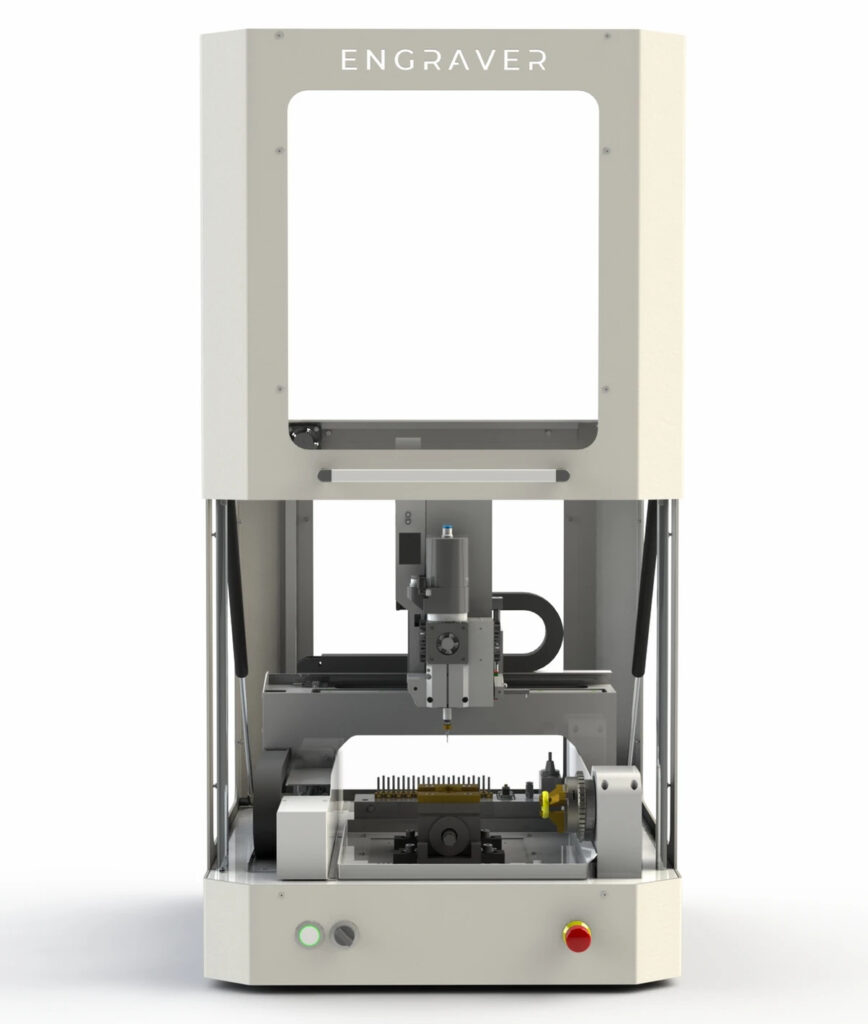

Innovative machine housing

The safety concept of the engraving machine consists of a stable sheet metal housing in cube format. The transparent glass panes provide an optimal view of all parts of the machine. The door of the CNC engraving machine is designed as a lifting door. This makes it very easy to open the machine and load it with jewellery and workpieces from the front. High-performance LED strips are installed in the upper area of the housing and thus always ensure optimal illumination of the machine interior. Impress your customers with the innovative housing design of the ENGRAVER.

Minimum quantity lubrication for cooling and lubrication of the tools

The standard equipment of the CNC milling machine includes fully integrated tool cooling and lubrication. This minimum quantity lubrication cools and lubricates the milling tools during machining by air and spray mist. Thus, significantly increase the tool life of your tools. In addition, the constant lubrication achieves a higher surface quality of your jewelry. The spray head of the lubrication system is built into the spindle block of the engraving machine and does not need to be adjusted.

Flat machining with the engraving machine for jewelry

In addition to engraving round jewelry, the ENGRAVER can also effortlessly handle flat workpieces. Flat workpieces, such as medallions, watches, bracelets or plates, are clamped in the engraving machine by means of a precision centering clamp. The clamping jaws can be rotated and changed without tools by means of a click system. We can also offer you individual clamping jaws for your jewelry pieces.

Patented measuring system for height compensation of curved surfaces

The newly developed and patented measuring system in the CNC engraving machine is unique. This system can accurately measure the curved surfaces of jewelry. The measured data is used to adjust the height profiles of the workpieces. Simple and two-dimensional drawings can easily and quickly engrave or mill 3D jewelry pieces, demonstrating the versatility of this design element. Simple and two-dimensional drawings can easily and quickly engrave or mill 3D jewelry pieces, demonstrating the versatility of this design element.In addition, you can reduce your tool wear enormously through the electronic height compensation.Using data optimized for your tools, it is no longer necessary to achieve a single cut for the engraving depth.

Application Examples of the Engraving Machine

Technical Data of the CNC Engraving Machine

Technical Data of the CNC Engraving Machine

| Technology | CNC Milling, CNC Diamond carving |

| Dimensions | 490 x 490 x 570 mm |

| Weight | approx. 55 kg |

| Max. Machining area (W x D x H) | 165 x 152 x 108 mm |

| Gantry clearance height | 99 mm |

| Max. Object size flat machining (W x D x H) | 202 x 205 x 98 mm |

| Max. Object size Round machining (Ø x L) | Ø 110 x 220 mm |

| Power supply | 230 V / AC |

| Spindle speed | variable adjustable 5.000 - 60.000 rpm |

| Clamping mechanism (spindle - tool) | Collet, Pneumatic 6 - 8 Bar |

| Number of tool places (magazine) | 23 + 1 (measuring tip) |

| Allowable tool shank diameter | Ø 2.35 mm, Ø 3 mm, Ø 3.175 mm, Ø 4 mm |

| Machine control software | EdingCNC |

| CAM Software | CamDRAW / Autodesk Fusion 360 |

| Tool cooling and lubrication | Lubrication / Cooling with liquid and air |

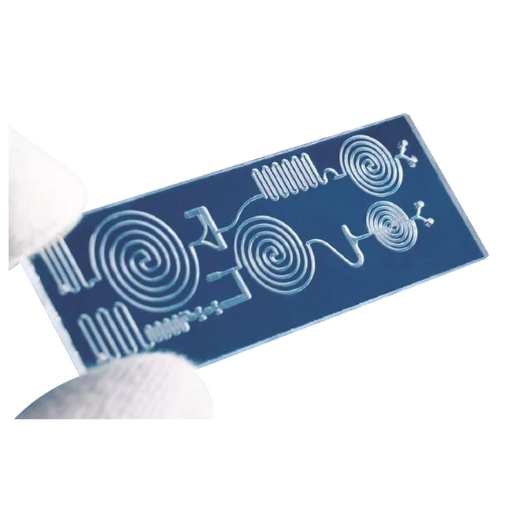

Picture of milling machine for jewelry